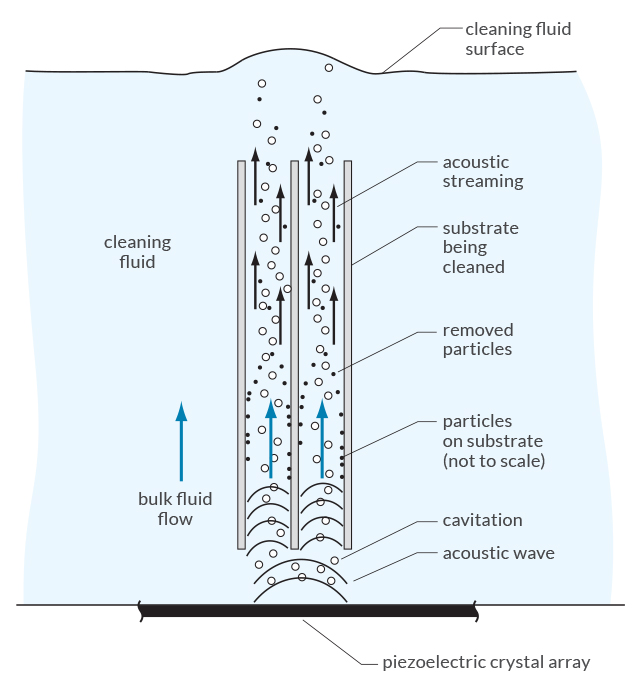

Acoustic cavitation is the generation and action of cavities, or bubbles, in a liquid. When an acoustic field is applied to a liquid, sound waves move through the liquid and produce variations in the liquid’s pressure. During the low-pressure portion of the acoustic wave, if the liquid pressure momentarily drops below the liquid vapor pressure, then cavities are formed. After forming, these bubbles are set in motion by the macroscopic pressure wave.

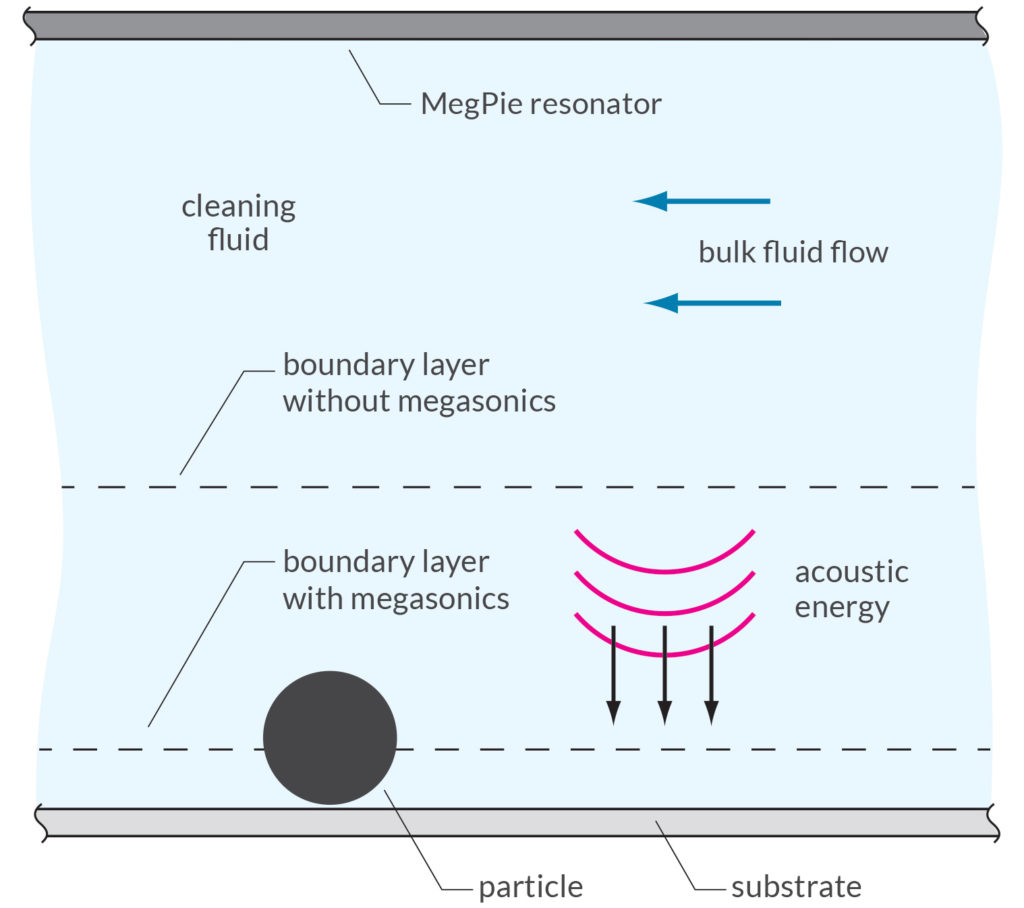

On a microscopic scale, fluid friction with the surface causes a thin layer of solution to move more slowly than the bulk solution. This slower moving layer is the boundary layer. The boundary layer effectively shields the substrate surface from fresh chemistry and shields attached contaminants from the forces of the bulk fluid flow. Figure 2 illustrates this effect when using a MegPie™.

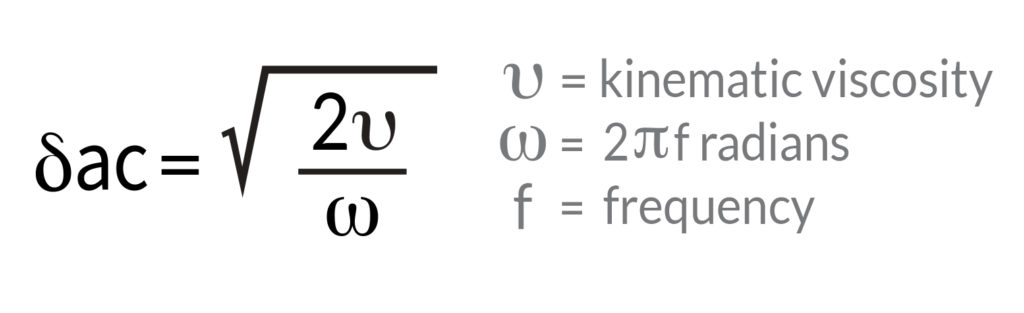

Boundary layer depth is a function of the frequency of the acoustic wave, the bulk fluid flow velocity, and chemistry properties such as viscosity and density. See Figure 3. Minimizing the boundary layer is essential for optimal particulate removal. A thinner boundary layer will expose smaller particles to the flow forces of the bulk fluid and will refresh chemistry at the surface more frequently, reducing cleaning times.

Megasonic cleaning has proven especially effective at removing submicron particles in part because it reduces the boundary layer. Megasonic frequencies reduce the boundary layer to less than 0.5 micron deep, compared to the boundary layer of 2.5 microns produced by lower ultrasonic frequencies. With a thinner boundary layer, more particles are exposed to the bulk fluid removal forces. This is especially important for detaching particles in the submicron range and for exposing smaller surface features to fresh chemistry and fluid flow forces.

The depth of the boundary layer also decreases with increasing velocity of bulk fluid flow. Megasonic energy boosts the bulk velocity because it creates acoustic streaming. When a sound field is applied to the fluid, a velocity is generated in the fluid, known as acoustic streaming. Acoustic streaming velocity is added to the bulk velocity. The combined higher velocity further reduces the boundary layer, exposing smaller particles to the bulk flow forces.

The controlled cavitations generated by megasonics act on contaminants within the thinner boundary layer. This phenomenon is unique to megasonic processes. Cavitations create localized micro-streaming forces within the boundary layer. Micro-streaming is an additional removal force unique to megasonic processing. This attribute is especially important in removing particles at the nanometer scale and accessing small surface features within the boundary layer that are otherwise shielded from the bulk flow forces.

High-frequency acoustic waves used in megasonic cleaning boost the bulk flow to lift a particle from a substrate. Megasonic also reduces the boundary layer depth, allowing removal of smaller particles. Finally, micro-streaming forces from cavitations within the boundary layer dislodge even smaller particles from the surface. Through the combination of the three factors, megasonic cleaning achieves >99% PRE when measured at 19 nm in volume production processes.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |